How A Pressurized Water Nuclear Reactor Generates Electricity

A nuclear reactor is a power generation device that converts heat from a nuclear reaction into electricity. The pressurized water reactor (PWR) is a specific type of nuclear reactor that uses pressurized water to transfer heat away from the nuclear reaction. The reactor gets its name from the fact that the water in the system is pressurized at around 150 times atmospheric pressure to prevent the water from boiling. The PWR is one of the most efficient and reliable types of nuclear reactors which is why it is used in United States nuclear submarines and aircraft carriers.

There are two major sections of the reactor to consider, the primary loop and the secondary loop. The primary loop is responsible for passing highly pressurized water past the fuel rods to heat up. The secondary loop is responsible for spinning a turbine to generate electricity and returning cooled water to the steam generator.

Components of Pressurized Water Reactor Primary Loop

A traditional PWR consists of a few major components in the primary loop that work together to safely transfer the heat from the reaction into liquid water. Each of the major components in the primary loop can be seen in Figure 1 below.

Fuel Elements

The nuclear reactor starts with a fission reaction, which involves heat and neutrons being released from the splitting of atoms. Uranium 235 (U-235) is a commonly used fuel because it is an exceptionally easy atom to split. One neutron colliding with a U-235 atom will cause that atom to split. Each time an atom of U-235 splits, two additional neutrons are released, these two neutrons could then collide with two other U-235 neutrons causing them to split.

The fact that each atom releases more neutrons than it takes to split is what causes this reaction to be so useful for continually generating energy. One problem with this is if left unchecked, the reaction can grow out of control causing an immense amount of energy to be released.

Control Rods

The control rods keep the reaction among fuel elements from growing out of control. The control rods are made of a material like cadmium, hafnium, or boron that absorbs neutrons before they can react with atoms.

With the control rods inserted between fuel elements, the reaction will only release a small amount of energy. As these fuel elements are moved upwards, fewer neutrons are absorbed into the rods and so these neutrons collide with other fuel elements. The movement of these control rods up and down is what determines how big the reaction is.

Steel Pressure Vessel

The steel pressure vessel contains the control rods and fuel elements. It also has inlets and outlets for water flow. For reasons beyond the scope of this document, the fission reaction is much more efficient if the water surrounding the fuel is in liquid form. Since the reaction causes the water to heat up to around 325° Celsius, the water needs to be pressurized at nearly 150 times atmospheric pressure to prevent boiling. Because of the large difference in pressure between the inside and outside of the vessel, this vessel must be very strong.

Pressurizer

The pressurizer is responsible for controlling the pressure in the primary loop and preventing the water from boiling. If the temperature of the water around the reactor increases beyond what is desired, water is allowed to flow into the pressure vessel, lowering the pressure in the loop, and causing the temperature to decrease back to safe levels. The opposite process occurs when the water is too cool.

Steam Generator

The steam generator is the component that connects the primary loop to the secondary loop. The steam generator is responsible for transferring heat from the water coming out of the reactor in the primary loop to other water which boils into steam in the secondary loop. Although this seems like a simple process it can be incredibly complex due to the need to keep the water that flows through the reactor at high pressure.

Concreate Containment and Shield

The containment and shield are important safety components of the reactor. Without the shield, a significant amount of radiation and neutrons will fly out of the reactor. These particles can cause cancer and other harmful side effects. Additionally, the containment may protect the environment surrounding the reactor in the event of a catastrophic event where the fuel becomes so hot that it melts through the steel pressure vessel. This situation is called a meltdown.

Components of Pressurized Water Reactor Secondary Loop

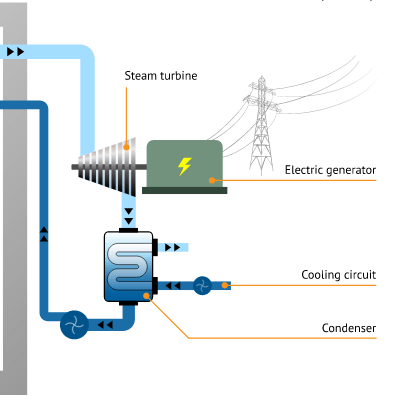

The secondary loop of the reactor is responsible for converting the pressure from steam into electricity and cooling the water down. This loop is also very similar to traditional steam generators which were invented almost 100 years before the nuclear reactor. Each of the major components in the secondary loop can be seen in Figure 2.

Steam Turbine and Electric Generator

The idea behind the steam turbine for the PWR is no different than other turbines that utilize the pressure of wind or water to spin a blade. The high-pressure steam from the steam generator moves from higher to lower pressure. The pressure on one side of the turbine is lower than the pressure on the other side, and so the steam pushes the turbine out of the way like how flowing water pushes a paddlewheel. The rotation of the turbine is then converted to electricity using an electric generator.

Condensor and Cooling Circuit

After the steam passes through the turbine, it must be cooled before it is sent back into the steam generator. If the water isn’t cooled sufficiently, then it won’t absorb enough heat from the primary loop in the heat exchanger. The condenser and cooling circuit cool the water back down and send it back to the steam generator in liquid form.

Conclusion

There are many components to a PWR that work in unison to safely and efficiently convert the heat from a nuclear reaction into electricity. The primary loop of the reactor contains highly pressurized and extremely hot water. The heat from this water is then transferred into cooler water which boils to steam to move a turbine and generate electricity.